Smart Compact in earthworks – automatic compaction to a specified target value

VA compactors from Hamm assure quality and process reliability

With the 20 t and 25 t HC 200i C VAand HC 250i C VA models, Hamm is now offering a range of compactors that enable automatic compaction to a specified target value in earthworks. The models are initially available in markets with EU Stage V / EPA Tier 4f exhaust emission standards, further markets will follow in due course. The abbreviation ‘VA’ stands for Variable Amplitude. An essential element of this technology from Hamm is the equally new, parameter-independent Smart Compaction Value (SCV).

With the Smart Compaction product family, Hamm has developed a range of solutions for smart and simple compaction. A further development that automates and simplifies compaction in earthworks and simultaneously improves quality and cost-efficiency has now been implemented in the new HC series models with VA drums. Following the successful launch of Smart Compact for asphalt construction at Bauma 2022, Hamm is now offering a corresponding solution for earthworks.

Smart Compact for Earthworks – simple and precise

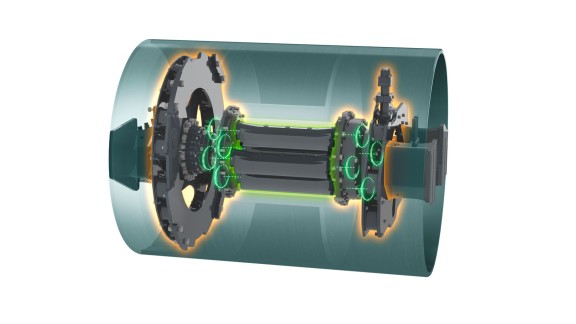

Operators can quickly and easily learn how automatic compaction works, as all the compactor driver has to do in daily operations on the construction site is choose between an automatic mode and a manual mode. While the amplitude is automatically regulated by the machine control system in automatic mode, manual mode allows the compactor driver to choose any one of five preset amplitudes. The function is operated via the already familiar Easy Drive display. In addition, a compaction target value in MN/m² based on typical load bearing capacity values can be specified before the start of compaction. In automatic mode, the compaction process is then controlled by Smart Compact until the specified target value has been achieved. The decisive factor here is the also newly developed Smart Compaction compaction value (SCV). The measurement is carried out by the Smart Compaction meter (SCM). The compaction value is also independent from key influencing factors, for example, the travel speed, the direction of travel or the frequency, which leads to high comparability of the measured values, even when using compactors of different weight classes.

Clear advantages in practice

The use of the new VA compactors brings various advantages for operators and construction contractors. For instance, the automatic compaction control not only ensures homogeneous compaction results, but also effectively prevents over-compaction or particle crushing at the same time. The VA compactors are therefore an attractive solution, as they make it easy for even inexperienced operators to achieve consistently high process reliability and quality. The cost-efficiency of construction projects is also improved through the fewer compaction passes required, the correspondingly lower diesel fuel consumption and the reduction of mechanical loads on the machine. The smaller number of passes required is naturally also accompanied by a corresponding reduction in CO₂ emissions. Furthermore, the reliable avoidance of jump operations caused by the machine control system leads to longer machine life. In view of the direct adjustment of the amplitude, the new technology can be considered to be an energy-efficient overall system.

Broad spectrum of applications and high centrifugal forces

With regard to potential applications, the new compactors are ideal for the compaction of cohesive, sandy, and coarsely-grained soils. Thanks to the high compaction forces that reduce the number of fewer passes required, VA compactors are also an effective solution for the compaction of thicker layers of rubble. This makes the machines a particularly versatile option for a variety of applications.

Public Relations

Reinhard-Wirtgen-Straße 2

53578 Windhagen

Germany

Compactor with VA drum

| Weight | 19,920 kg |

| Drum width | 2,140 mm |

| Exhaust emissions category | EU Stage V / EPA Tier 4 |

Compactor with VA drum

| Weight | 24,645 kg |

| Drum width | 2,140 mm |

| Exhaust emissions category | EU Stage V / EPA Tier 4 |